Products Search

Products Categories

Company News

- 10-29Major brands in the color steel plate industry staged cross-border "dramas"

- 10-29The four major strategies will constitute the key factors for the modern color steel plate industry

- 10-29Grasping the trend of consumer upgrading: color steel plate enterprises understand consumer thinking

- 10-29What is the development direction of color steel plate enterprises in the era of "quality consu

- 10-29New trends in the color steel plate market:Industry reshuffle intensifies

Boxing color steel plate, color coated plate manufacturer

Detailed introduction

| Scope of use | Architectural decoration | material quality | colour steel |

|---|---|---|---|

| purpose | building | Type | composite material |

| characteristic | Strong weather resistance and bright color |

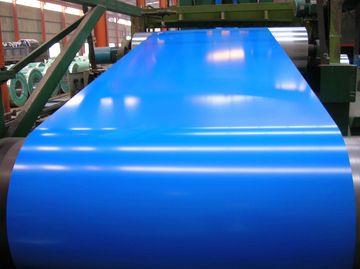

The market use of color coated panels is mainly divided into three parts: construction, home appliances, and transportation. Among them, the construction sector accounts for the largest proportion, followed by the home appliance industry, and the transportation industry only accounts for a small portion.

1. Architectural color coated panels are generally made of hot-dip galvanized steel plates and hot-dip aluminum-zinc steel plates as substrates. They are mainly processed into corrugated panels or sandwich panels that conform to polyurethane, and are used to construct roofs, walls, and doors of industrial and commercial buildings such as steel structure factories, airports, warehouses, and freezers.

2. Home appliance color plates are generally made of galvanized and cold rolled sheets as substrates, used for the production of refrigerators and large air conditioning systems, freezers, bread machines, furniture, etc.

3. In the transportation industry, galvanized and cold rolled plates are generally used as substrates, mainly for oil pans, automotive interiors, and so on.

Color coated steel plate Color coated steel plate uses galvanized steel plate as the substrate. In addition to zinc protection, the organic coating on the zinc layer plays a covering and isolation role, which can prevent the steel plate from rusting and has a longer service life than galvanized steel plate. It is reported that the service life of coated steel plate is 50% longer than that of galvanized steel plate.

However, in different regions and usage areas, the service life of color coated panels with the same amount of zinc plating, same coating, and same coating thickness will vary greatly. For example, in industrial areas or coastal areas, due to the action of sulfur dioxide gas or salt in the air, the corrosion rate accelerates and the service life is affected.

Galvanized color coated rolled sheet is a specific attractive substitute for wood and other materials, and its prestige in the construction industry is also evident. The reason for this is because it has advantages such as anti fading, weather resistance, and resistance to powdering. Galvanized color coated rolled sheets minimize the maintenance cost of the building, while various colors indicate the structure and coating, making it highly flexible and optional.